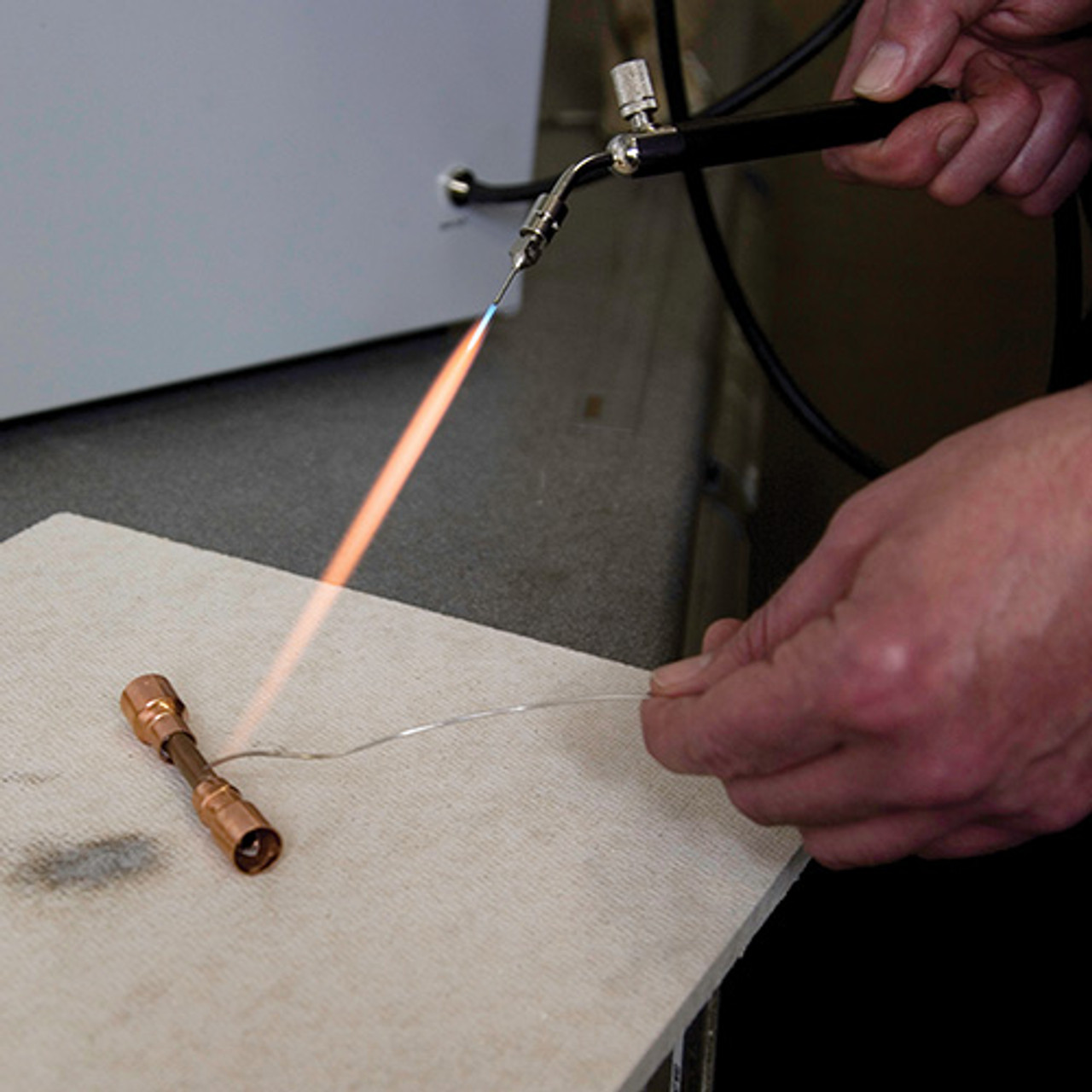

The Model 800 Aquaflame Torch is ideal for soldering Silver, Gold, Platinum, Stainless Steel and some Titanium Alloys, and can also handle heavy soldering. Made of the highest quality components the Aquaflame torch system is a complete soldering system—bottled gas with pressurized fuel tanks are a thing of the past. The powerful yet compact generator converts distilled/deionized water into hydrogen and oxygen gases by electrolysis. Minimal maintenance is required and to prove the exceptional construction and use, Aquaflame Torch Systems boast a full 2-year warranty! A nice range of tips (from #18 which is a 0.90mm bore size to #24 which is 0.31mm) are supplied with the Model 800 unit to perform standard soldering tasks such as re-sizing or re-tipping. The Aquaflame Torch system is a must for any jeweler/repair facility. Extensively used in the jewelry industry, Aquaflame Systems are also used in the dental and other technical manufacturing industries since they are ideal for precision soldering and micro welding. The Model 800 can produce gas up to 120 liters/hour using 50ml of distilled water per day. Reaches a maximum temperature of 3,300°C

A clean precise environmentally friendly flame is obtained by using Methyl-Ethyl-Ketone (MEK). MEK leaves no residue on the surgical steel tips. This is far safer than the toxic/hazardous Methanol also known as Methyl Alcohol which is commonly used in other competitive torches. The operator will find the light-weight torch handle easy to hold and for safety, it contains a built-in Flashback Arrestor. When using liquid flux or flux based paste solders, you will see less fire scale which is commonly found when working on silver. Aquaflame Torches are also widely used for acrylic flame polishing (edge polishing on acrylic) in plastic fabrication as this method requires no other materials or compounds and can finish intricate shapes quickly and easily. The Model 800 can polish a 10mm thickness in one pass; 2 minute per meter. Generally uses 0.80 kW of electricity. The Model 800 can have one additional operator for a total of 2 by purchasing a 830-1084 for that additional operator - sold separately.

Complete with 2-year manufacturer's warranty; however since servicing required every 12 months, or 4,000 working hours, which ever comes first, for warranty to apply; we suggest purchasing the services kit see 830-1081 for Model 800. Foot print measures 16"Lx11"Wx15"H (400mm x 280mm x 380mm). Proudly made in the United Kingdom with CE approval.

NOTE: Requires (1) of electrolyte (830-0044). Also requires (1) of MEK (830-0042). Both sold separately.

| Equipment Information | Model 500 | Model 800** | Model 1200** |

| Reference Number | 830-1005 | 830-1006 | 830-1007 |

| Gas production | 75 lt/h | 120 lt/h | 240 lt/h |

| Distilled water use (per day) | 30ml | 50ml | 100ml |

| Maximum flame temperature | 3300c | 3300c | 3300c |

| Electrical usage | 0.50 kW | 0.80 kW | 1.20 kW |

| Flash back fitted | Yes | Yes | Yes |

| Torch tips range supplied | 20 - 24 | 18 - 24 | 17 - 24 |

| Torch tips bore size supplied (mm) | 0.60 - 0.31 | 0.90 - 0.31 | 1.00 - 0.31 |

| Service recommended period | 4000 working hours | 4000 working hours | 4000 working hours |

| Warranty period* | 2 years | 2 years | 2 years |

| Length | 16" (400mm) | 16" (400mm) | 17.5" (440mm) |

| Width | 8" (200mm) | 11" (280mm) | 12.5" (320mm) |

| Height | 12" (300mm) | 15" (380mm) | 15.5" (395mm) |

Shipping Weight | 44lbs/18kg | 66lbs/33kg | 110lbs/49kg |

| Flame Polishing Details | |||

| Chemical for flame positioning | MEK | MEK | MEK |

| Thickness that can be polished in one pass | 5mm | 10mm | 15mm |

| Typical polishing times (per meter) | 1 min | 2 mins | 3 mins |

*Servicing required every 12 months for warranty to apply.

**Non-stock, special order and must ship via truck.

Due to continuous improvements, some of the above details may change without notice.

Custom Field

Item Height 15"

Item Length 16"

Item Width 11"

Model 800

__SDS File 1 https://cdn.gesswein.com/images/sds/11702_0_BR0189a_Gesswein_Methy_Ethyl_Keytone_MSDS.pdf

__AddtoCart Notes3 Catalog Page # 555

Use melt up to 20gms

__Instruction Manual https://cdn.gesswein.com/images/Manual_Instrns/AQUFLAME-GETTING-STARTED.pdf

__UOM Description Each

__uomdescrip Each

__techspec Y

Reference Gas Production: 120 lt/hr